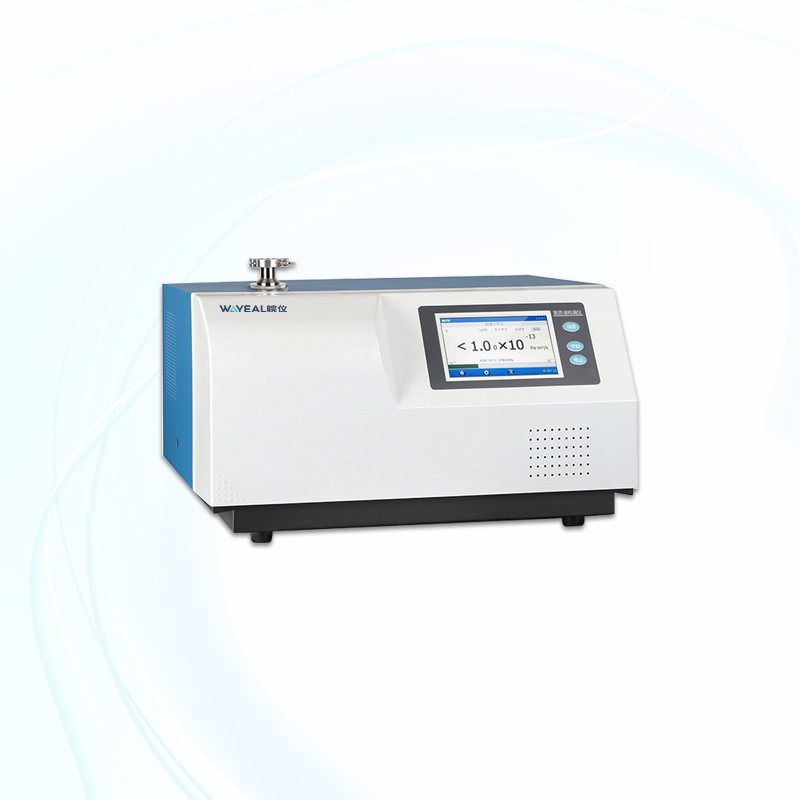

Product Description of Helium Leak Detector:

This helium leak detector with a mini leak detection rate of 2.5*10-9 Pa.m3/s in sniffer mode and 5*10-13 Pa.m3/s in vacuum mode. With its powerful helium leak detection capabilities, this sniffer leak detector is the perfect tool for anyone who needs to quickly and accurately identify leaks in their systems. Whether you are working with complex industrial machinery or simple household appliances, this product is guaranteed to get the job done.

Technical Parameters of SFJ-261Helium Leak Detector:

| roduct Name |

Helium Leak Detector |

| Diamension |

592 x498 x370mm |

| Operating temperature |

0~40°C |

| Detectable Quality |

2, 3, 4 (H2, He3, He4) |

| User Interface |

7inch Color Touch Screen |

| Detection Method |

Helium Leak Detection |

| Mini Leak Detection Rate(Pa.m3/s)/Vaccum Mode |

5*10-13 Pa·m3/s |

| Communication Interface |

RS232/485, USB*2 |

| Max Allowable Leak Detection Pressure (Pa) |

1500 |

| Ion Source |

2pcs, Iridium Coated Yttrium Oxide, Automatic Switching |

| Main Features |

Mass Spectrometer Leak Detector, Helium mass spectrometer Leak Detector, helium leak testing |

| Mini Leak Detection Rate(Pa.m3/s)/Sniffer Mode |

5*10-9 Pa·m3/s |

| Start Time |

2min |

| Leak Detection Port |

DN25KF |

| Power |

AC220V, 50Hz/60Hz |

| Language |

Chinese/English |

Applications of Helium Leak Detector:

Helium mass spectrometer leak detectors (HLDs) are critical, high-precision quality control instruments in the new energy battery industry. Their unparalleled sensitivity is essential for ensuring the safety, performance, and longevity of lithium-ion batteries.

Here are the key application cases of helium leak detectors in the new energy battery industry:

1.Cell (Cylindrical, Prismatic, Pouch) Hermeticity Testing

This is the most fundamental and widespread application. Any leak in a cell can lead to electrolyte evaporation, ingress of moisture/oxygen, and ultimately, failure or thermal runaway.

Method: Vacuum Chamber (Bombing) Test. This is the industry gold standard.

Bombing: Finished cells are placed in a sealed pressure chamber filled with a helium-air mixture (e.g., 5% He, 95% air) at a specified pressure for a set time.

Trapping: If a leak path exists, helium is forced into the cell.

Testing: The cells are then transferred to a test vacuum chamber connected to the HLD. Any helium trapped inside the cell will leak out under vacuum, and the HLD quantifies the exact leak rate.

Pouch Cells: Seal edges.

Prismatic/Cylindrical Cells: Welded seams, jellyroll canning, and terminal connections.

2.Battery Pack (Module/Pack) IP Rating Validation

Battery packs require high Ingress Protection (IP) ratings (e.g., IP67) to prevent water and dust from entering in harsh environments.

Method: Sniffer Probe Testing or Vacuum Chamber Testing.

Sniffer Method: The pack is slightly pressurized with a helium-air mixture from the inside. An operator or robot then uses the HLD's sensitive sniffer probe to meticulously scan all external seams, gaskets, connectors, cooling ports, and busbar interfaces. The probe instantly detects and locates any leak points.

Chamber Method: Smaller modules or entire packs are placed in a large vacuum chamber. The chamber is evacuated, and helium is sprayed on suspected external leak points. The HLD detects if helium is drawn into the chamber through a leak.

3.Cooling System Leak Testing

Liquid cooling plates and internal coolant channels are ubiquitous in modern EV battery packs. A leak can cause short circuits and coolant loss.

Method: Pressure-Vacuum Sniffer Test.

The cooling system is pressurized with a helium-air mixture.

The entire battery pack or module is placed in a vacuum chamber and evacuated.

Alternatively, the sniffer probe is used to scan the exterior of the cooling channels and joints.

4.Safety Valve (Vent) Functionality Test

A safety valve must remain perfectly sealed under normal operating pressures but open reliably at a specified pressure to vent gases and prevent explosion.

Method: Precise Sniffer Test.

The valve is tested at a pressure just below its designed opening threshold.

The sniffer probe is used to check for any micro-leaks around the valve seal.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!