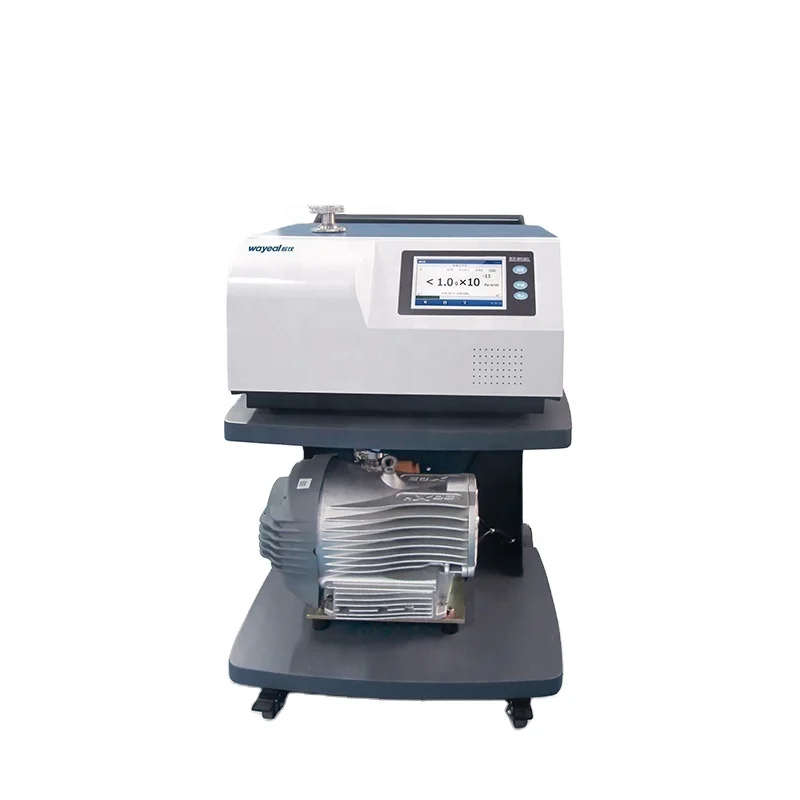

Dry Pump Helium Leak Detector for Wafer Leak Detection SFJ-231D

Technical Parameters of Helium Leak Detector SFJ-231D

| Product name |

Helium leak detector SFJ-231D |

| Minimum detectable leak rate(Pa·m³/s)/ vacuum mode |

5.0*10-13 Pa·m3/s |

| Minimum detectable leak rate(Pa·m³/s)/ sniffer mode |

5.0*10-9 Pa·m3/s |

| Maximum allowable leak detection pressure (Pa) |

1500 |

| Response time |

<1s |

| Startup time |

≤2min |

| Detectable quality |

2, 3,4(H2 ,He3, He4) |

| Man-machine interface |

7" color LCD touch screen |

| Ion source |

2pcs, iridium coated yttrium oxide, automatic switching |

| I/O Input/output interface |

8 inputs and 8 outputs |

| Communication interface |

RS232/485, USB*2 |

| MES interface |

standard |

| Leak Detection port |

DN25KF |

| Power Supply |

AC220V, 50Hz/60Hz |

| Operating temperature |

0~40°C |

| Language |

English |

| Leakage rate display |

Figure, bar chart, curve chart |

| Diamension |

645*678*965mm |

Application of SFJ-231D Helium Leak Detector for the Wafer

In helium mass spectrometry leak detection technology, the application of dry pumps (oil-free dry vacuum pumps) mainly depends on the working conditions of the equipment to be inspected, the cleanliness requirements and the technical requirements of helium mass spectrometry leak detectors (e.g. Wayeal SFJ-231D).

Detection Method: Vacuum Spray Helium Method (High-Sensitivity Mode)

1: System Evacuation and Baseline Calibration

Evacuate to base pressure: Etching chamber: ≤0.1Pa (dry pump + molecular pump combination); CVD/PVD chamber: ≤10⁻³ Pa (higher requirements for coating equipment).

Leak detector calibration: Use a standard leak reference (e.g., 1×10⁻⁷ Pa·m³/s) to calibrate the SFJ-231D and verify instrument response linearity.

Step 2: Helium Spray Detection

Detection area: O-ring grooves, bolt holes, VCR/VCO metal seals, weld joints, Ceramic insulators, copper gaskets, Bellows connections.

Helium spray operation:

Use a handheld helium spray gun (with 0.1 mm fine-tuning nozzle) at 3-5mm distance from the detection point. Move at 5cm/s speed, dwelling 2-3 seconds per point (SFJ-231D response time <1 sec). Adjust helium pressure to 0.2-0.3MPa to avoid airflow disturbance.

Step 3: Leak Point Determination and Recording

Leak rate: Semiconductor equipment allowable leak rate: Typically ≤1×10⁻⁹ Pa·m³/s (per SEMI standards).

Data recording: When the SFJ-231D displays a leak rate peak, mark the leak point with a highlighter pen.

Save leak rate curves and location data (export via USB).

Step 4: Re-inspection and Verification

Perform a second helium spray on identified leaks to confirm repeatability.

After repairing major leaks, re-evacuate to base pressure and conduct a full re-inspection.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!