Introduction of Helium Leak Detector:

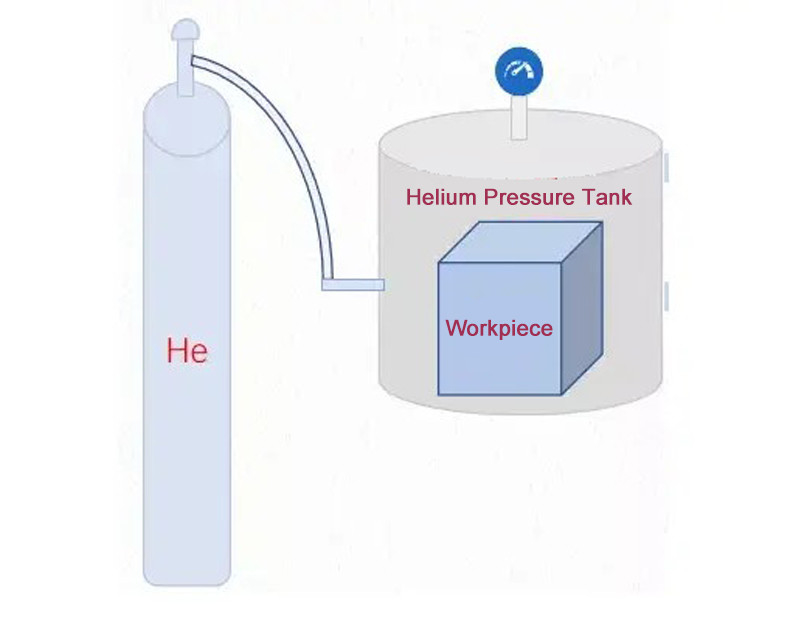

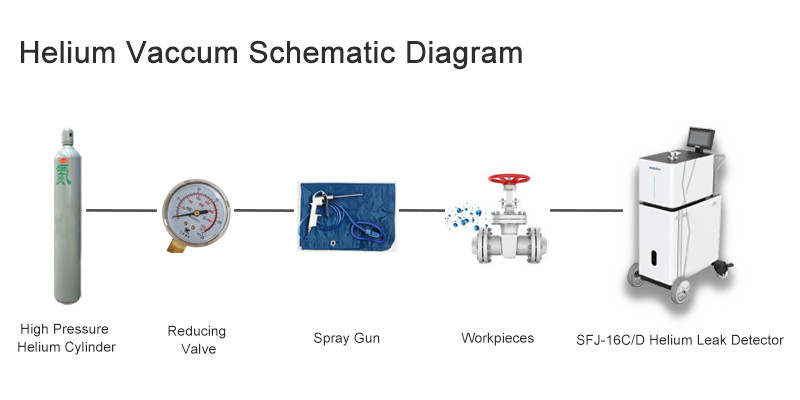

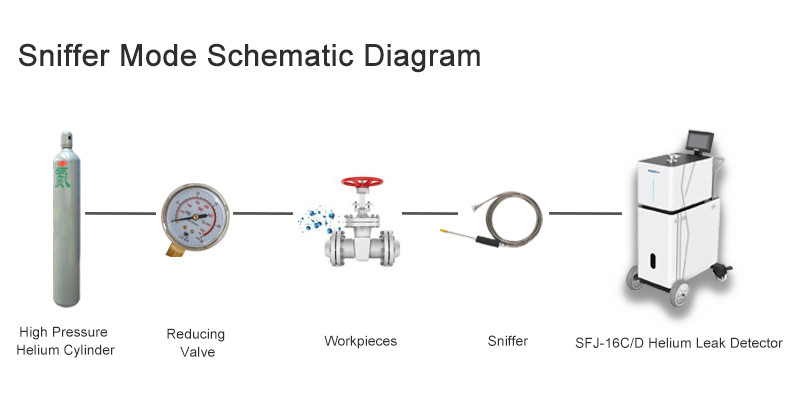

Helium leak detector is an indispensable procedure that plays a critical role in various industries, from aerospace and automotive to medical devices and energy sectors. Helium leak detectors operate based on the principle of mass spectrometry. When a system is suspected of having a leak, it is evacuated and then filled with helium. Being one of the smallest and lightest molecules, helium has an innate ability to pass through even the tiniest of openings. The helium that escapes through these leaks is drawn into the leak detector, where it is ionized and passed through a magnetic field. This process separates the helium ions from other gases. A detector then measures the quantity of helium ions, allowing for precise identification and localization of leaks.

Technical Parameters of Helium Leak Detector:

|

SFJ-16D High Efficiency Automatic Helium Leak Testing System Helium Leak Detector

|

|

Product Name

|

Helium Leak Detector

|

| Detection Method |

Helium Mass Spectrometer |

| Leak Detection Port |

DN25KF |

| Leak Rate Display |

Numbers, Bar Charts, Graphs |

| Response Time(s) |

<1s |

| User Interface |

7inch Color Touch Screen |

| Operating temperature |

0~40°C |

| Max Allowable Leak Detection Pressure (Pa) |

1800Pa |

| Communication Interface |

RS232/485, LAN |

| Detectable Quality |

2, 3, 4 (H2, He-3, He-4) |

| Mini Leak Detection Rate(Pa.m3/s)/Sniffer Mode |

2.5*10 -9 Pa.m3/s |

| Mini Leak Detection Rate(Pa.m3/s)/Vacuum Mode |

5.0*10-13 Pa.m3/s |

| Startup Time (min) |

≤1.58 |

| Backing Pumps |

Scroll Vacuum Pump |

| Diamension |

755*467*1180mm |

| Power Supply |

220V, 50Hz/60Hz |

| Language |

Chinese/English |

Applications of Helium Leak Detector:

Military: In military applications, helium leak testing is vital for ensuring the reliability of weapons systems, communication equipment, and vehicles. The method is used to detect leaks in everything from missile casings to submarine hulls, contributing to national security.

Automotive: In the automotive industry, helium leak testing is used for testing fuel tanks, radiators, air-conditioning systems.

Aerospace: Ensuring the integrity of fuel systems, oxygen supply lines, and other critical components is paramount in aerospace applications.

Support and Services:

Our Product Technical Support and Services for the Helium Leak Detector include:

Online Resources: Access our comprehensive online library of manuals, FAQs, and troubleshooting guides designed to help you understand and operate your Helium Leak Detector effectively.

Software Updates: Keep your Helium Leak Detector up-to-date with the latest software enhancements and performance improvements by downloading the latest firmware from our support portal.

Technical Assistance: Our skilled team of technical support engineers is available to provide expert advice and assistance with any questions or issues you may encounter with your Helium Leak Detector.

Training Services: We offer specialized training programs to help you and your team get the most out of your Helium Leak Detector, covering operation, maintenance, and best practices for leak detection.

Parts and Accessories: We supply a full range of genuine parts and accessories specifically designed for the Helium Leak Detector to maintain its performance and extend its service life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!