Introduction of Helium Leak Detector

Helium leak detection technology provides detection of the smallest leaks and is good for outside/in and inside/out leak detection. In outside/in helium leak detection, vacuum is pulled on the container to be leak checked or vacuum is pulled through the part. Helium is sprayed in very small amounts on the suspected leak areas of the part and the vacuum pulls it through if there is a leak. The helium leak detector can then detect and quantify the helium coming through and provide the signal and display the leak rate.

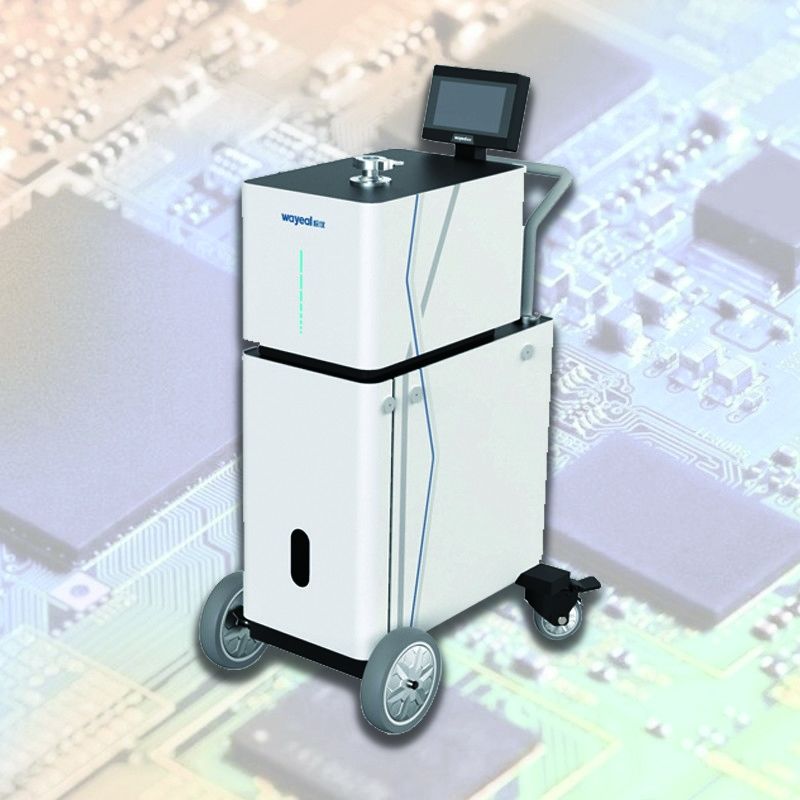

Overall, the Helium Leak Detector represents a significant advancement in the field of leak detection technology. It combines high sensitivity, broad gas detection capabilities, and advanced data display and communication features. This tool is indispensable for professionals who demand the highest level of accuracy and reliability in their vacuum leak detection devices. With its robust construction and user-friendly interface, the Helium Leak Detector is set to become the go-to choice for industries looking to safeguard their operations against the detrimental effects of gas leaks.

Technical Parameters of Helium Leak Detector:

|

Precise He Leak Tester Vaccum Helium Leak Detector 220V 50Hz

|

|

Product Name

|

Helium Leak Detector

|

|

Detection Method

|

Helium Mass Spectrometer

|

|

Dimension

|

755 * 467 *1180mm

|

| Mini Detectable Leak Rate(Pa·m3/s)/Sniffer Mode |

2.5*10-9 Pa·m3/s |

| Mini Detectable Leak Rate(Pa·m3/s) Vacuum Mode |

5.0*10-13 Pa·m3/s |

| Maximum Detectable Leak Rate(Pa) |

1800 |

| Response Time (s) |

<1 |

| Startup Time (min) |

≤1.58 |

| Deteatable Quality |

2,3,4(H2, He-3, He-4) |

| HMI |

7inch Color LCD Touch Screen |

| Ion Source |

2pcs, Iridium coated yttrium oxide, automatic switching |

| Backing Pump |

Rotary Vane |

| I/O Input/Output Interface |

8 Inputs, 8 Outputs |

| Communication Interface |

RS232/485, LAN |

| MES Interface |

Standard |

| Leak Detection Port |

DN25KF |

| Power Supply |

220V, 50Hz/60Hz |

| Operating Temperature |

0~40°C |

| Language |

Chinese/English |

| Leakage Rate |

Fiure, Bar Chat, Curve |

Applications of Helium Leak Detector:

Pharmaceutical Industry:

Pharmaceutical industry

By using helium leak detection early in the development process, companies can improve the quality of their drug delivery system. This not only saves money and time, but also improves safety.

Medical Devices Industry:

Helium leak testing is the most common tracer gas method in the medical device industry. Helium or a helium-air combination is used to pressurize the test component within a vacuum chamber. The chamber enclosing the part is next evacuated, generating a vacuum that allows the helium to enter the chamber through any leaks. A mass spectrometer designed to detect helium takes a sample of the vacuum chamber and ionizes any helium detected. Even a small amount of helium is easily detected in this method.

Methods of Helium Leak Detection (Helium Leak Detector)

Helium Vacuum Method

Helium Hood Method

Helium Hood Method

Negative Pressure Method

Vacuum Chamber Helium Leak Detection and Recovery System (external filling)

Sniffer Method

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!